OUR PROCESS

Contact us

Contact us first by submitting a quote request. We will then contact you to confirm your service request with instructions for disassembling your parts and shipping them to our facility.

the magic happens

We will inspect your parts, contact you if we notice anything out of sorts, and then start the Vapor Honing process.

happy ending

Once your parts have gone through the Vapor Honing process, we inspect them, box them up and ship them back to you. Please note: Payment (including return shipping) will be collected after inspection.

What is vapor honing?

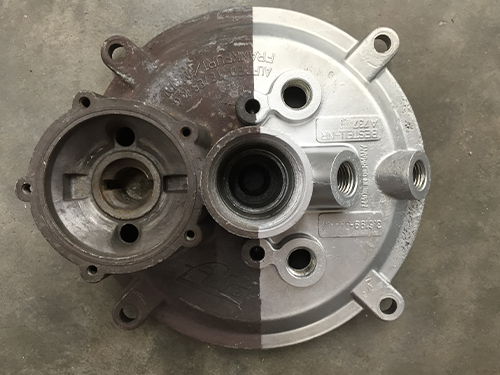

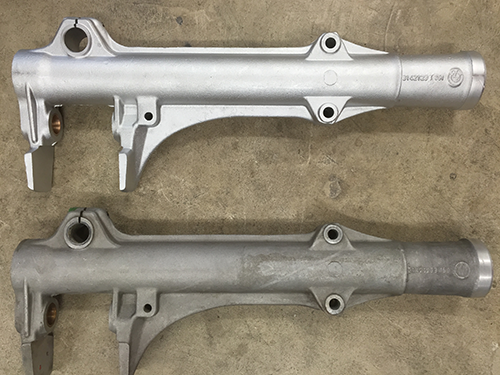

Vapor honing (also referred to as vapor blasting or wet blasting) is a surface refinishing process used to clean and restore surfaces. Instead of dry abrasive media (used in sandblasting), it uses a combination of water, compressed air, detergents with finer and gentler media to remove oxidized metal and corrosion. The process also seals the pores of the aluminum making it look better longer, leaving it with a much shinier and smoother surface.

how does it work

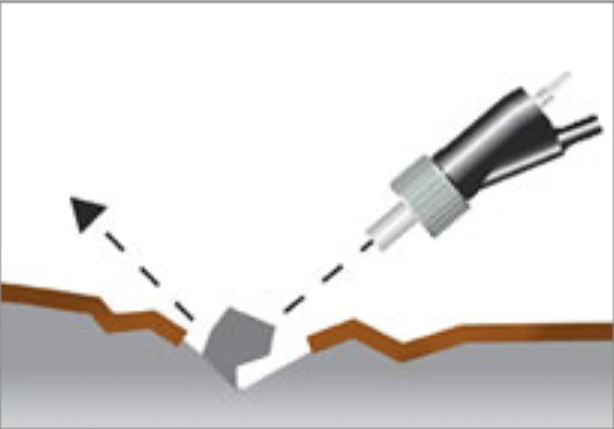

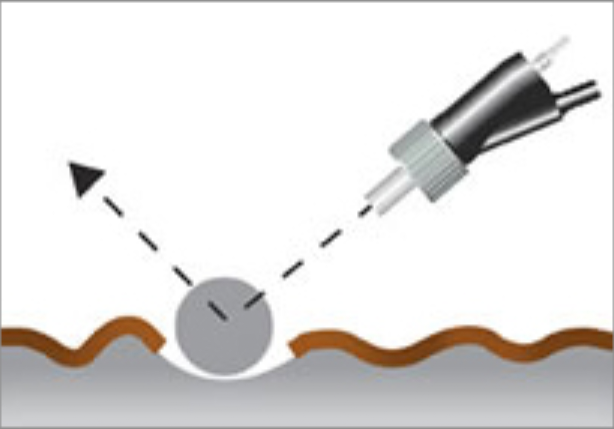

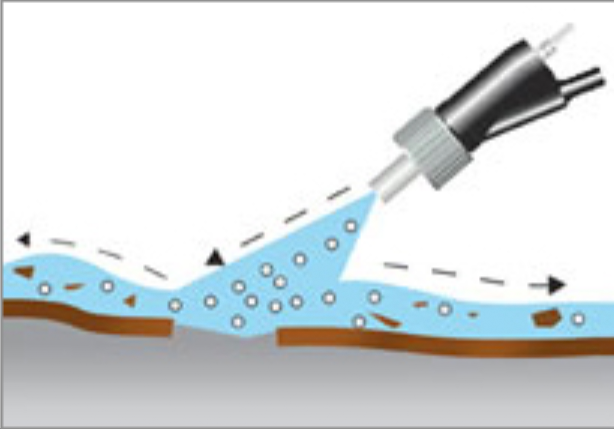

The key to vapor blasting is that the finish is produced through flow of water borne abrasive, giving a finer finish due to the flushing action of the water. No media is impregnated into the component, nor is there any dust created by the break-up of media, unlike dry blasting where the finish is produced by sheer force of media impact. A specially designed glandless polyurethane pump agitates water and media into a slurry, and pumps it to the blast gun. At the same time this slurry is pumped at approximately 2 bar to the nozzle, and air is introduced at the blast gun to accelerate the slurry and its cleaning effect on impact, albeit cushioned.

The illustrations above show the different natures of grit, bead, and vapor blasting. The aggressiveness of dry grit and bead blasting are shown in the first two illustrations which demonstrate the severe 80 degree ricochet that occurs when using these methods. The third illustration shows the gentler, but just as effective, vapor blasting method. The ricochet of media is reduced due to the cushioning from the water: the angle of the media is changed producing a lapping effect traveling across the surface, giving an even satin/polished finish.

TYPICAL APPLICATIONS

- Cleaning of dies & molds

- Removal of paint, rust, scale, carbon & similar deposits in engineering industries

- Surface preparation prior to bonding, re-painting or re-coating

- Satin finishing of stainless steels & other special materials

- Removal of small burrs from manufactured components

PRICING

Minimum fee - $65

The shop fee for small jobs that take less than an hour.

Vapor honing RATE - $75/HR

The hourly rate for vapor honing services only. This does not include any time spent disassembling, wrenching or preparing parts for vapor honing.

SHOP RATE - $65/HR

Hourly rate for any disassembling, wrenching or preparing parts for vapor honing services.

Ready to get started?

Request Quote

Click the button below to request a quote and details about hiring Vapor Honing Restorations Portland for your next project.

Contact Us

Call us

(503) 512-9681

FAQ

Click below to see frequently asked questions about the Vapor Honing process and our services.